Local Exhaust Ventilation Thorough Examination Testing for U-POL

The Client

U-POL is a world leader in automotive refinishing products, specialising in high-quality polyester body fillers, polyurethane coatings, aerosols, adhesives, and paint-related products.

The Challenge

To endorse the company’s ethical conduct, safety, and environmental management ethos, we carry out regular Local Exhaust Ventilation (LEV) Thorough Examination and Testing of the company’s LEV systems and fume cupboards, under COSHH (Control of Substances Hazardous to Health) Regulation 9 (Maintenance, examination, and testing of control measures).

The Solution

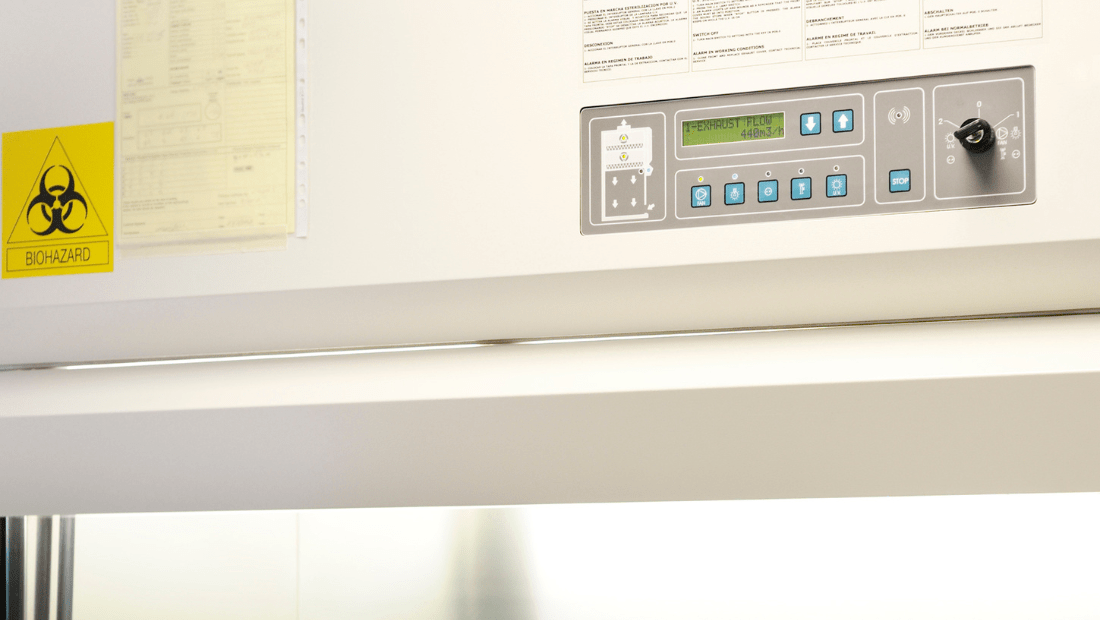

The Local Exhaust Ventilation (LEV) Thorough Examination and Testing of the factory’s production line LEV systems, including on-tool extraction and laboratory fume cupboards, was conducted and quantitative measurements were taken to compare with the previous test results, with the positions of the dampers set at previous balanced positions.

A visual appraisal was made of the effectiveness of the extraction hoods and filters. Tyndall illumination was also used for testing each air cleaner’s performance, if recirculating back into the workspace, at the discharge/air outlet. A visual inspection and appraisal was also carried out on each of the LEV systems on the condition and suitability of each system with regards to the process and hazardous substances concerned.

Equipment used during this test included: TSI VelociCalc (Model TA465-P Serial no: TA 4651316004), Electric Manometer, Hot Wire Anemometer, 100mm Vane Anemometer, Pitot Tube, Dust Lamp and Smoke tubes.

Tony Smedley was the Test Engineer, assisted by Steven Edwards. Tony holds the following qualifications for the Testing of LEV systems:

- BOHS W501 Measurement of Hazardous Substances – understanding of the techniques for assessing exposure to hazardous substances in the workplace and an understanding of how exposure information can be used to assess risk.

- BOHS P604 Performance Evaluation, Commissioning and Management of Local Exhaust Ventilation Systems – practical and theoretical understanding of how to fully commission or recommission an LEV system, to ensure that it has been designed properly and can effectively control airborne contaminants in the workplace.

- BOHS W201 Basic Principles in Occupational Hygiene – understanding the broad principles in occupational hygiene as the basis for anticipation, recognition, evaluation and control of hazards that can be encountered in the workplace.

Tony also has over 20 years of experience in ventilation engineering and workplace environment control.

Steven Edwards has also successfully completed the BOHS W501 Measurement of Hazardous Substances.

The Results

This work ensured compliance with COSHH Regulations, kept employees protected by making sure that exposures are adequately controlled, and helped the client avoid potential fines and prosecutions. Keeping LEV systems in good working condition can also keep them quieter and more energy efficient. A Thorough Examination and Test can also help identify other risks, such as potential explosions and hazards from contaminants accumulating in the ducting.