Emissions Testing

Our MCERTs and UKAS accredited Emissions Testing services help to keep you compliant to environmental permits.

eDAS®

Get increased visibility of your environmental performance to help identify cost savings, improve decision support, environmental awareness, and business efficiency

eDAS® ➔

MCERTS Stack Emissions Testing

Demonstrate your compliance against regulated emission limits with our MCERTS accredited Stack Emissions Testing service.

MCERTS Stack Emissions Testing ➔

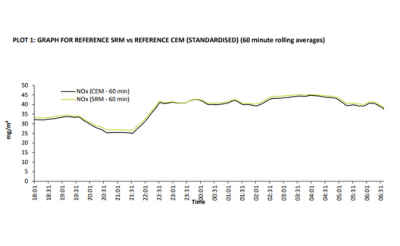

BS EN14181 QAL2/AST Calibration of CEMS

Evaluate the functionality of your Continuous Emissions Monitoring System (CEM) to ensure it has been correctly installed and the calibration is still valid.

BS EN14181 QAL2/AST Calibration of CEMS ➔

Odour Monitoring

Ensure compliance with your permit, reduce nuisance complaints and improve environmental conditions by monitoring odour with our fully MCERTS and UKAS accredited service.

Odour Monitoring ➔

Bioaerosol Monitoring

Keep your workforce safe and remain compliant to Environment Agency standards with complete Bioaerosol Monitoring and analysis.

Bioaerosol Monitoring ➔

Greenhouse Gas (GHG) Emissions Testing

Manage your greenhouse gas emissions and reduce your organisation's carbon footprint with GHG emissions testing.

Greenhouse Gas (GHG) Emissions Testing ➔

CEMS Navigator

Get a tailored CEMS solution to fit your specific requirements. You will receive guidance through the design, procurement and management of the right CEMS solution for you.

CEMS Navigator ➔

CEMS Servicing

Maintain full confidence in your continuous emissions monitoring system with a comprehensive CEMS Service Agreement.

CEMS Servicing ➔

Medium Combustion Plant Directive (MCPD) Stack Testing

Demonstrate your compliance with the Medium Combustion Plant Directive (MCPD) with MCERTS and UKAS accredited Stack Emissions Testing.

Medium Combustion Plant Directive (MCPD) Stack Testing ➔